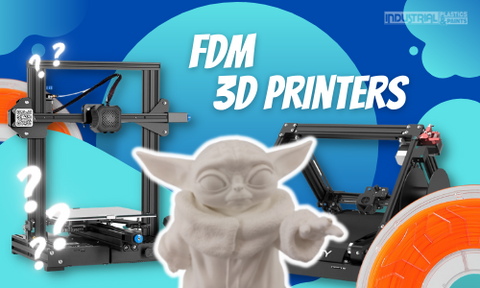

As we read in the last 3D printing article, filament is tough to choose when first getting started, and choosing a machine can be just as confusing! To keep things simple we will separate our learning into three parts. Today's section we will learn the differences between the different methods of 3D printing. As well as we will learn about the differences in types of FDM and resin printers. Be sure to read part two and three for a full comprehensive look at some machines.

Today's article will go over the Pro's and Con's of each printer per category of a typical maker, as well as briefly explaining the different types of machines. We will break it down by how the machine will be utilized, whether you are using the printer for prototyping, cosplay, manufacturing, and so on.

What types of 3D printers are there? Are they not all the same?

There are a few different types of 3D printing processes. Firstly, and most commonly is Fusion Deposition Manufacturing, or FDM. There are many different types of FDM printers to choose from as well as different extruding and mechanical sub types. FDM printers use filament spools to create objects.

Secondly we have masked stereo-lithography apparatus, or MSLA resin printing. This is a newer type of technology that utilizes a monochrome display to cure resin with high fidelity. MSLA printers were based off of an older method of printing with resin commonly referred to as SLA or DLP. MSLA is commonly mislabeled as LCD printing as it uses an LCD screen.

Thirdly we have stereo-lithography apparatus or SLA, and digital light projection or DLP resin printers. Resin printing with LCD, DLP, or SLA machines are fundamentally very similar, the differences are in the details of how a laser or a display cures layers of resin. SLA technology uses a combination of lasers and mirrors to project and cure areas of resin, whereas DLP printing utilizes light and mirrors. LCD printing utilizes a display to cure resin directly.

Shown is Creality Ender-3 V2 and CR-30

FDM: How It Works

FDM printers are a 3 axis X-Y-Z machine. X, Y, and Z axis are coordinated side to side, back to front, and bottom to top. Filament is heated and extruded through an extruding system with a small brass nozzle to force molten plastic filament into a smaller diameter to then be deposited by the print head. The molten filament is deposited onto the print bed layer by layer to build your model.

These types of printers have become the staple of makers due to their inexpensive price, at only a few hundred dollars, as well as their versatility. Filament spools of PLA can cost as low as $15 per kg, naturally making this the most logical choice for most just getting started into the hobby! There are as many filaments available on the market as imaginable, such as wood filled, metal filled, flexible, or soluble support.

See some of our available filaments.

One is likely to see FDM printers in production mills, or rapid prototyping shops, as well as workshops for costuming.

FDM: Advantages

- Strong

- Inexpensive

- Large format to compact sizes

- Ideal for beginners

- Enormous market of filament available

- Highly customization

- Create functional pieces

Shown is CREALITY LD-002H and HALOT-SKY

MSLA(LCD): How It Works

A MSLA resin printer cures one layer at a time using typically by today's standard a 2K or 4K monochrome display. A resin vat with a clear PTFE film sits directly on top of a LCD screen and the build plate is lifted up with each new layer. This method of resin printing can yield multiple highly detailed prints in the time it takes to print one using FDM printing. Most commonly these printers have a small print volume, but the machines will typically fit directly onto a workspace counter top.A MSLA printer is just as budget friendly as its FDM counterpart when purchasing an entry model. Printers start at just a few hundred dollars, and resin can cost as low as $35 per litre. However the resins cost at least double what a spool of filament would at for one kilogram. There are many different types of resins, including but not limited to, clear, flexible, loss wax, quick curing, and extra tough.

See some of our available resins.

One is more likely to find a resin printer in a professional lab, as you can produce end user models with no post processing.

MSLA(LCD): Advantages

- Highly detailed

- Print multiple objects in a fraction of the time

- Compact form factor

- Near silent

- Clear and translucent resins

Fidelity: What Do Prints Look Like?

Both MSLA and FDM printing pose obstacles when it comes to getting a perfectly printed part. FDM printers, simply by their nature can produce models with wall or layer separations, and elephant footing, or ghosting. But in general depending on the filament and .gcode settings I personally find FDM to be more structurally sound. Simply put, a MSLA printer will produce the highest quality model with nearly zero post processing. However, again this is dependent on your slicing settings, but almost entirely, your resin choice, as these prints I find to be very fragile.

A MSLA printer will reliably produce a higher quality and deeper resolution fidelity ten times better than an FDM printer ever could. That's not to say you could not tune your FDM printer to rival that of an MSLA printer, but the time it would take to produce objects is just not worth it. You could produce ten of the same tiny object in the time it would take to make one.

Another advantage to MSLA/LCD printing is screens are rapidly increasing in quality, with little change to the MSRP. Just one year ago I purchased my first 2K resin printer, and that blew my mind. Just now one year later we have the first 6K resolution printers announced and on the market, you can imagine how impressive this would have been to me prior.

Things To Consider: Additional Notes

When printing any time, bed adhesion is an ever constant issue. Strategically placing, modifying, and using bed adhesives is essential. Whatever the type of printing, one should always consider the optimal orientation of the model, and if applicable you should be using a bed adhesive. See one of our solutions; Magigoo Original. I for one use bed adhesives on every single print. A key advantage of doing this is easier print release if not using a spring steel bed, no need for rafts or brims in most cases, and peace of mind knowing you can simply walk away when starting a new print.

Always consider what type of objects you will be producing before purchasing either type of machine. In addition you will want to consider the amount of effort you are capable of dedicating to post-processing and cleanup. Not to mention printing in certain filaments or resin can produce strong odor irritants for those whom are sensitive.

Keep these considerations in mind, or write them down for part two: Choosing your first FDM printer.

![3D Printing: Choosing your first 3D Printer – What's what!? [1/3]](http://goindustrial.com/cdn/shop/articles/1-1060x400w_345x300_crop_center.png?v=1698075623)